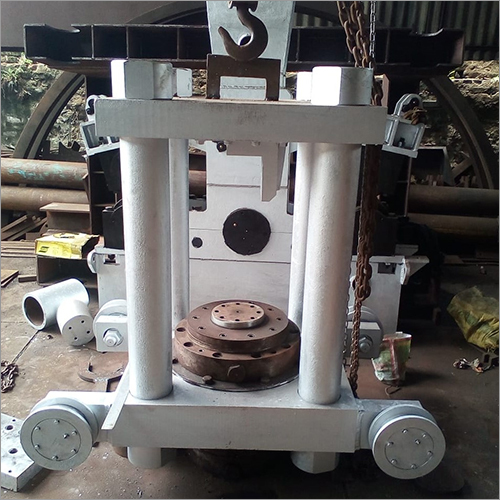

Auto Hot Billet Shearing Machine

Price 1000000 INR/ Unit

MOQ : 1 Unit

Auto Hot Billet Shearing Machine Specification

- Features

- High efficiency, automatic feeding, robust construction, safety interlocks

- Drive

- Electric/Hydraulic

- Noise Level

- <85 dB

- Production Capacity

- 5 to 20 TPH (as per requirement)

- Motor Power

- Up to 60 kW

- Cooling System

- Water Cooled / Air Cooled

- Lubricating System

- Automatic Centralized Lubrication

- Accuracy

- 2 mm (depending on billet size)

- Voltage

- 380-415V, 3 Phase

- Model No

- Customized as per Client

- Connectivity Options

- Remote Monitoring Optional

- Frequency

- 50 Hz

- Frame Type

- Heavy Duty Fabricated Frame

- Operating Temperature

- Up to 1200C billet temperature

- Control System

- PLC Controlled

- Power Rating

- As per model (typically 30-60 kW)

- Machine Type

- Automatic Hot Billet Shear

- Product Type

- Auto Hot Billet Shearing Machine

- Technology

- Automatic Hot Shearing

- Power Source

- Electric

- Operating Type

- Automatic

- Power

- 20-60 kW (Varies by machine size)

- Pressure

- Hydraulic, adjustable as required

- Surface Treatment

- Painted / Anti-corrosive Coating

- Dimension (L*W*H)

- Approx. 3500 x 1800 x 2100 mm

- Weight (kg)

- Approx. 8000 Kg

- Color

- Industrial Blue/Grey

- Usage & Applications

- Cutting hot billets in steel rolling mills, forging units, metal processing plants

- Max. Shear Force

- Up to 350 Tons

- Operator Panel

- Touchscreen HMI

- Ambient Humidity

- 90% RH

- Billet Size Range

- 50 mm to 150 mm diameter/width

- Installation Type

- Floor Mounted

- Cutting Cycle Time

- 4-8 seconds per billet

- Safety Features

- Emergency stop, guards, interlocks

- WorkingSpeed

- Adjustable up to 15 cuts/min

- Service Support

- On-site / Remote

- Hydraulic Oil Type

- Recommended ISO VG-68 or as specified

- Painting Type

- Powder Coated Industrial Finish

- Spare Parts Availability

- Readily Available

- Blade Stroke

- Variable, hydraulic actuated

- Shearing Blade Material

- High-Grade Alloy Steel

Auto Hot Billet Shearing Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 1 Unit Per Week

- Delivery Time

- 120 Days

About Auto Hot Billet Shearing Machine

We are engaged in rendering abroad assortment of Auto Hot Billet Shearer. It is availed in a bulk quantity at cost effective rates. This shearer is made as per the latest engineering standards used in the industry. It is useful as to detect the shear blade position. Auto Hot Billet Shearer is suitable for versatile purpose by cutting of allows and sheet metal materials. It is made as per latest engineering standards and industrial norms.

Precision and Flexibility for Demanding Environments

Engineered for industrial reliability, the Auto Hot Billet Shearing Machine features a heavy-duty fabricated frame and state-of-the-art automatic controls. Its variable cutting cycle time and adjustable working speed accommodate production needs between 5 and 20 tons per hour. Designed for billets with varying diameters or widths, it maintains an impressive cutting accuracy of 2 mm and operates efficiently under demanding temperatures and high humidity.

Safety, Maintenance, and Operator Ease

Safety is paramount in our design, which is equipped with emergency stops, interlocks, comprehensive guarding, and an intuitive touchscreen HMI. Maintenance is made seamless due to centralized automatic lubrication, easy monitoring, and immediate access to spare parts. The powder-coated finish and anti-corrosive surface treatment ensure durability even in aggressive industrial atmospheres.

FAQ's of Auto Hot Billet Shearing Machine:

Q: How does the Auto Hot Billet Shearing Machine operate and what is its control system?

A: The Auto Hot Billet Shearing Machine operates automatically using a PLC-controlled system, managed through an easy-to-use touchscreen HMI panel. Operators can adjust variables such as blade stroke, pressure, and cutting speed to suit different billet sizes and production requirements.Q: What types of billets and environments is this machine suitable for?

A: This machine is optimized for cutting hot billets sized between 50 mm and 150 mm diameter or width, commonly used in steel rolling mills, forging units, and metal processing plants. It is robustly built to operate in ambient humidity up to 90% RH and can handle billet temperatures up to 1200C.Q: When is on-site or remote service support available and how is spare parts availability ensured?

A: Service support is available as per client needs, either on-site or remotely via connectivity options. Spare parts are readily accessible, ensuring minimum downtime and uninterrupted production.Q: Where should the machine be installed, and what are the installation requirements?

A: The Auto Hot Billet Shearing Machine is designed for floor-mounted installation in industrial environments. It requires a stable surface, access to an electrical supply (380-415V, 3 Phase, 50 Hz), and recommended use of ISO VG-68 hydraulic oil or as specified.Q: What is the process for adjusting the working speed and cutting cycle time?

A: The machine's working speed-up to 15 cuts per minute-and cutting cycle time (4-8 seconds per billet) can be easily adjusted via the HMI operator panel, allowing operators to optimize for desired production throughput and billet characteristics.Q: How does the built-in safety system benefit operators and facility managers?

A: Equipped with emergency stops, protective guards, and interlock features, the safety system minimizes accidents and ensures a secure working environment. This protects both operators and machinery, while also aiding compliance with occupational safety standards.Q: What are the main benefits of using this automatic hot billet shearing machine?

A: Key benefits include high efficiency, precise automatic feeding, robust construction, quick and accurate cutting cycles, reduced labor intervention, and hassle-free maintenance with automatic lubrication and remote monitoring capabilities.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry