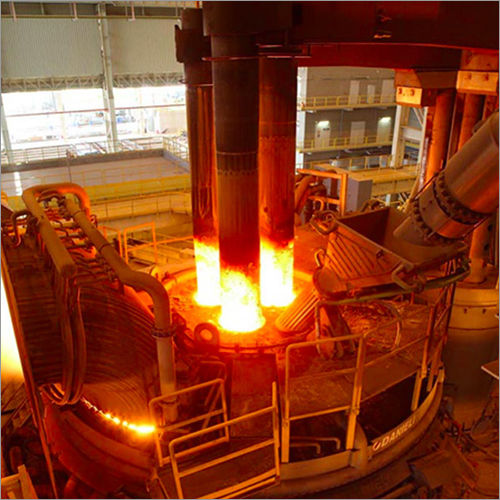

Electric Arc Furnace Machine

Price 7800000 INR/ Unit

MOQ : 1 Unit

Electric Arc Furnace Machine Specification

- Feature

- High Efficiency, Fast Melting Cycle

- Rating

- High Power Output

- Condition

- Brand New

- Type

- Electric Arc Furnace

- Usage

- Industrial Melting

- Power

- Up to 10,000 kW

- Voltage

- 380-440 V

- Size

- Customizable (various sizes available)

- Dimensions

- Varies per model (consult supplier)

- Weight

- Approx. 8-35 Tons (depending on specification)

- Application

- Steel Manufacturing, Alloy Production

- Fuel Type

- Electric

- Capacity

- 2 ton to 50 ton

- Max Temperature

- 1800°C

- Melting Time

- 35 to 60 minutes per batch

- Furnace Shell Material

- Heavy Duty Steel

- Lining Material

- Magnesia Carbon Brick

- Electrode Diameter

- Up to 500 mm

- Door Type

- Hydraulically Operated

- Safety Features

- Overload Protection, Emergency Shut-Off

- Phase

- Three Phase

- Transformer Capacity

- Up to 12 MVA

- Environmental Compliance

- Low Emissions, Dust Collection Included

- Installation Type

- Fixed Installation

- Maintenance

- Low Maintenance

- Operation Mode

- Automatic and Manual

- Cooling System

- Water Cooled

- Control System

- PLC Automated

Electric Arc Furnace Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 1 Unit Per Day

- Delivery Time

- 90 Days

About Electric Arc Furnace Machine

Our firm is occupied in rendering a wide array of Industrial Electric Arc Furnace Machine. It is well equipped with a finest grade of tools which increase its durability. Apart from this, provided machine is used for melting the metal. It is also suitable for producing a mini steel structural bars as well as steel rods. Industrial Electric Arc Furnace Machine is used for secondary steelmaking. It enables a high-voltage electrified arcs to melt scrap steel for conversion into liquid steel.

Efficient and Powerful Melting Solutions

This Electric Arc Furnace stands out with its high power output and fast melting cycle, making it ideal for demanding steel and alloy manufacturing processes. Its heavy-duty construction ensures durability, while the water-cooled system and advanced PLC automation streamline operations for optimal results even under intensive use.

Advanced Safety and Environmental Compliance

Operator safety is prioritized with integrated overload protection, emergency shut-off, and a fully automated control system. The low-emission design includes an effective dust collection unit, reducing environmental impact while maintaining compliance with stringent industry standards in India and globally.

Customizable for Diverse Industrial Needs

Available in a wide range of capacities (from 2 to 50 tons) and customizable sizes, this furnace is designed for flexibility. Whether replacing older furnaces or establishing a new facility, users can consult the supplier to configure a solution that precisely matches their operational demands.

FAQ's of Electric Arc Furnace Machine:

Q: How does the Electric Arc Furnace operate, and what are its primary applications?

A: The furnace operates using electric arcs generated between graphite electrodes (up to 500 mm in diameter) to melt steel scrap or alloy materials. It is primarily used in industrial steel manufacturing and alloy production, capable of handling batch sizes from 2 to 50 tons.Q: What are the benefits of the PLC automated control system in this electric arc furnace?

A: The PLC automated control system ensures precise and consistent operation, allowing seamless transition between automatic and manual modes. This enhances process reliability, streamlines monitoring, and improves overall safety by enabling rapid responses to operational changes.Q: Where can the Electric Arc Furnace be installed, and what installation type does it require?

A: This furnace is designed for fixed installation within industrial melting facilities and steel plants. Dimensions vary per model, so it is essential to consult the supplier for layout planning and site preparation guidance based on your operational requirements.Q: What environmental compliance features does this furnace offer?

A: The furnace incorporates a low-emissions design and an included dust collection system to minimize air pollutants. These features help facilities adhere to stringent environmental standards and reduce their overall ecological impact during melting operations.Q: When is maintenance needed, and how is it managed for this furnace?

A: Designed for low maintenance, the furnace requires routine checks as per supplier recommendations. Key components such as water cooling systems, hydraulic doors, and magnesia carbon lining should be regularly inspected to ensure efficient, trouble-free operation.Q: What safety features are included to protect operators and the facility?

A: Safety measures include overload protection, an emergency shut-off function, and heavy-duty steel construction. The hydraulically operated door and PLC control reduce manual intervention, further decreasing potential risk during operation.Q: What is the process time for melting, and how does the furnace's efficiency benefit production?

A: Each batch melts in approximately 35 to 60 minutes at temperatures up to 1800C. The fast cycle times and high power output significantly enhance production throughput, enabling facilities to meet high demands with energy-efficient performance.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry